Ensuring the quality of sheet metal parts during sheet metal processing is a comprehensive process involving multiple links and factors. The following is a professional and detailed description to guide how to ensure the quality of sheet metal parts:1. Preliminary preparationDesign and process review:Before sheet metal processing, conduct a full design and process review to ensure that the design is reasonable and the process is feasible.Consider factors such as material selection, structural rationality, and process feasibility to reduce the probability of problems in the production process.Material selection and procurement:Choose suppliers with good reputation to ensure that the quality of raw materials meets relevant standards and requirements.Strictly inspect each batch of raw materials, including material properties, dimensional accuracy, surface quality, etc.According to actual needs, select raw materials with high toughness, high tensile strength, high yield strength, low hardness and high corrosion resistance.2. Equipment and process controlEquipment calibration and maintenance:Regularly calibrate and maintain the processing equipment to ensure the accuracy and stability of the equipment.Replace wear parts, lubrication equipment, calibration equipment, etc. to ensure the normal operation of the equipment and processing accuracy.Process parameter setting:During the process design stage, the processing parameters of each process are reasonably determined, such as tool selection, cutting speed, feed speed, etc.Optimize and adjust according to the actual situation to ensure the execution of process specifications and the accuracy of process parameters.Operation specifications:Establish clear operating procedures and process flows to ensure the accuracy and consistency of each operation step.Train operators to improve their skills and work awareness so that they can better master the processing technology and operation specifications.3. Quality control and inspectionSet quality control points:During the sheet metal processing process, set corresponding quality control points, such as material inspection, process inspection, finished product inspection, etc.Perform strict quality inspection and testing on each quality control point to ensure that the quality of sheet metal meets the requirements.Dimension detection:Use precision measuring tools to measure the dimensional parameters of sheet metal parts, compare them with the design drawings, and determine whether the dimensions are qualified.Material detection:Conduct chemical composition analysis, metallographic analysis, etc. to confirm that the materials used for sheet metal parts meet the requirements.Strength test:Evaluate the mechanical properties of sheet metal parts through tensile tests, compression tests, bending tests, etc.Appearance inspection:Observe the surface of sheet metal parts with the naked eye to see if there are obvious cracks, scratches, depressions, spots and other defects.IV. Process controlCombine and optimize the process:Combine and optimize the process of each process to ensure the continuity and stability of the processing process.Develop detailed work instructions to ensure the standardization and normalization of each operation link.Establish a good communication mechanism:Establish a good communication mechanism to record and feedback problems encountered during processing in a timely manner.Take timely corrective and preventive measures for problems to prevent them from expanding or recurring.V. Environmental controlMaintain appropriate temperature and humidity:Maintain appropriate temperature and humidity in the processing workshop to prevent deformation and corrosion of materials due to humidity changes.Maintain a clean processing site:Maintain a clean processing site to prevent impurities and dust from affecting the surface of the product.Ensure good ventilation:Ensure good ventilation in the processing workshop to prevent harmful gases from affecting workers and products.6. Record and traceabilityRecord and save:Record and save the operation and inspection results of each process for traceability and analysis.Analysis and improvement:By analyzing the recorded data, timely discover and solve potential quality problems.Provide references and lessons for improvement and optimization in the subsequent processing process.Through the comprehensive application of the above measures, the quality of sheet metal parts in the sheet metal processing process can be effectively guaranteed. This requires not only professional technology and management capabilities, but also the participation of all employees and the awareness of continuous improvement.

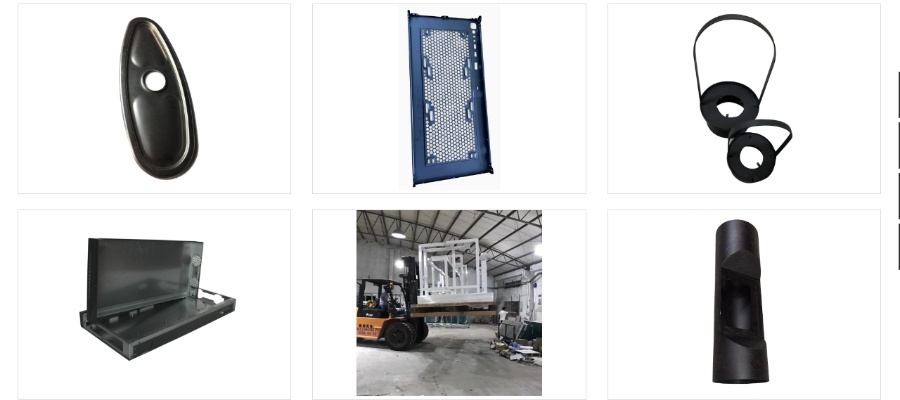

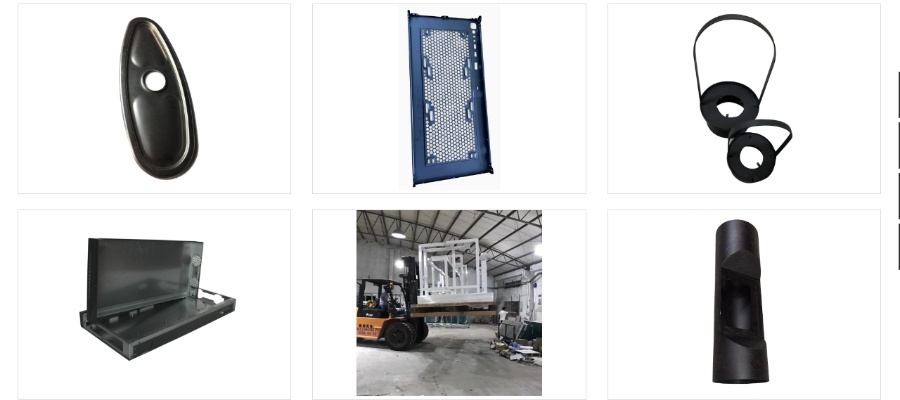

With the development of science and technology, automated machinery and equipment are also constantly improving, and our processing methods have also changed a lot. Compared with traditional manual processing methods, Dongguan sheet metal processing methods undoubtedly have greater advantages. And with the changes in science and the continuous advancement of Dongguan sheet metal processing technology, what problems are needed in the processing process?In the process of Dongguan sheet metal processing, all are designed and processed according to requirements, so it is necessary to master the changes in the product scale of Dongguan sheet metal processing, and the scale of sheet metal processing products must meet the standard requirements on the drawings. In the process of sheet metal processing in Dongguan, there are many kinds of equipment used, such as cutting machines. In the cutting process, we should pay attention to the factors that affect the cutting accuracy, the hardness of the material and the cutting allowance of the cutting machine, the processing length and the reliability of the workpiece clamping. Maintenance of Dongguan sheet metal processing equipment is one of the important means for the long-term operation of the equipment. It is also one of the important prerequisites for improving production results.DongGuan Win-Leading Hardware Technology Co., Ltd. has developed over the years and specializes in hardware products such as hardware molds, stamping products, sheet metal bending, laser cutting, CNC processing, etc. with excellent manufacturing level and service attitude. It is named for its influence in the world manufacturing industry and its product supply capacity that is all over the world. Welcome new and old customers to call for inquiries.

With the development of science and technology, automated machinery and equipment are also constantly improving, and our processing methods have also changed a lot. Compared with traditional manual processing methods, Dongguan sheet metal processing methods undoubtedly have greater advantages. And with the changes in science and the continuous advancement of Dongguan sheet metal processing technology, what problems are needed in the processing process?In the process of Dongguan sheet metal processing, all are designed and processed according to requirements, so it is necessary to master the changes in the product scale of Dongguan sheet metal processing, and the scale of sheet metal processing products must meet the standard requirements on the drawings. In the process of sheet metal processing in Dongguan, there are many kinds of equipment used, such as cutting machines. In the cutting process, we should pay attention to the factors that affect the cutting accuracy, the hardness of the material and the cutting allowance of the cutting machine, the processing length and the reliability of the workpiece clamping. Maintenance of Dongguan sheet metal processing equipment is one of the important means for the long-term operation of the equipment. It is also one of the important prerequisites for improving production results.DongGuan Win-Leading Hardware Technology Co., Ltd. has developed over the years and specializes in hardware products such as hardware molds, stamping products, sheet metal bending, laser cutting, CNC processing, etc. with excellent manufacturing level and service attitude. It is named for its influence in the world manufacturing industry and its product supply capacity that is all over the world. Welcome new and old customers to call for inquiries.