What are the reasons for poor workpiece quality caused by poor stamping effect caused by CNC stamping?

Publish Time: 2024-07-30

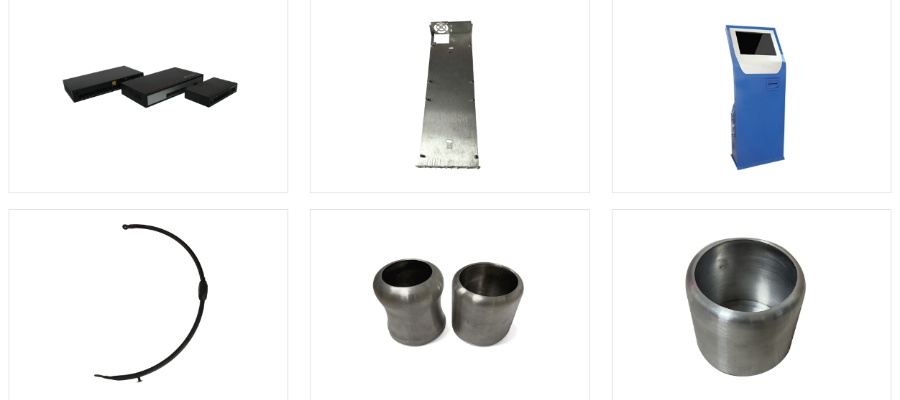

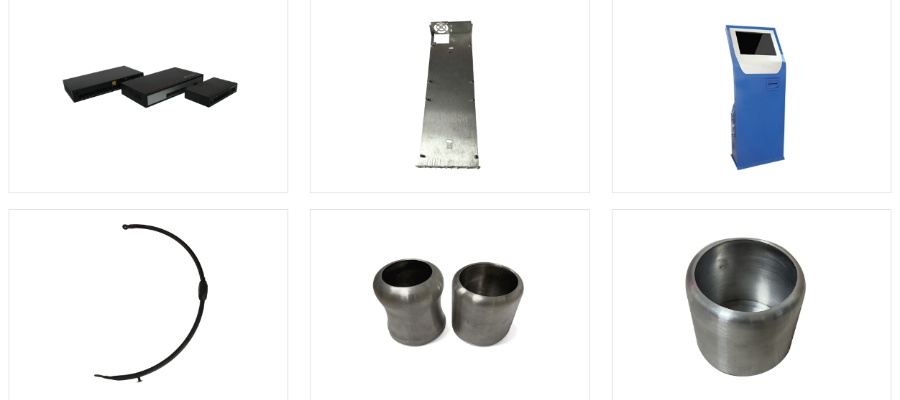

The reasons why CNC stamping causes poor stamping effects and poor workpiece quality involve multiple aspects, mainly including materials, molds, equipment, processes, and operations. The following is a specific analysis of these reasons:1. Material aspectRaw material quality: The size, hardness, tensile properties, and material toughness of the raw materials do not meet the standards, which will directly affect the stamping effect. For example, materials that are too hard or too soft may cause uneven material deformation during the stamping process, resulting in defective products.Material surface state: If there are debris, oil stains, oxide scales, etc. on the surface of the material that have not been cleaned up, it will cause defects such as crushing and scratches during the stamping process.2. Mold aspectMold design: Unreasonable mold design, such as improper selection of mold gap, punch shape, and mold material, will affect the stamping effect. Too large a mold gap will cause the size of the stamped part to be too large, and too small a gap will easily cause burrs and deformation.Mold manufacturing accuracy: The processing accuracy and assembly accuracy during the mold manufacturing process directly affect the quality of the stamped parts. Low mold accuracy will lead to unstable dimensions and poor surface roughness of the stamped parts.Mold wear: The mold will gradually wear out during use. If it is not repaired or replaced in time, the dimensional accuracy of the stamped parts will decrease and the surface quality will deteriorate.3. EquipmentEquipment performance: The performance difference of CNC punch presses will affect the stamping effect. Some low-end CNC punch presses are relatively lacking in rigidity and accuracy, and it is difficult to cope with the processing needs of difficult workpieces.Equipment maintenance: After long-term use of the equipment, if it is not regularly maintained and maintained, the equipment accuracy will decrease, thereby affecting the stamping effect.4. ProcessStamping process parameters: Unreasonable process parameter settings during the stamping process, such as stamping speed, pressure, temperature, etc., will affect the stamping effect.Stamping sequence: For complex stamping parts, the rationality of the stamping sequence will also affect the stamping effect. If the stamping sequence is improper, the workpiece may be deformed or cracked.5. OperationOperation skills: The skill level of the operator directly affects the stamping effect. If the operator is not proficient in equipment operation or is not familiar with the stamping process, it is difficult to ensure the quality of the stamping parts.Operation specification: Irregular behavior during operation, such as failure to operate according to the operation procedures, failure to conduct necessary inspections and adjustments, etc., may lead to poor stamping results. Many metal parts are processed by sheet metal processing, and the processing step of forming products in sheet metal processing is CNC stamping. The quality of stamping parts is affected by many factors, mainly the stamping die of the stamping machine, or the problem of pneumatic clamps. At present, the market competition in every industry is constantly developing fiercely. The same is true for the CNC stamping industry. Therefore, the quality of products is one of the main reasons affecting corporate competition.In the process of CNC stamping, what are the reasons for the failure of the workpiece? It may be that the difference between the mold and the feeding table is too large. The looseness of the CNC stamping fixture clamp will affect the offset of the feeder plate. Or it is a local failure of CNC stamping, mostly caused by loose screws. CNC stamping driver. Driver alarm, if the CNC stamping machine fails, it will cause the driver alarm. Reduce the occurrence of CNC stamping failures. Ensure the quality of stamping parts, reduce the phenomenon of substandard product quality, and improve corporate productivity.DongGuan Win-Leading Hardware Technology Co., Ltd. has developed over the years and specializes in hardware products such as hardware molds, stamping products, sheet metal bending, laser cutting, CNC processing, etc. with excellent manufacturing level and service attitude. It is known for its influence in the world manufacturing industry and its product supply capacity that is the best in the world. Welcome new and old customers to call for inquiries.

Many metal parts are processed by sheet metal processing, and the processing step of forming products in sheet metal processing is CNC stamping. The quality of stamping parts is affected by many factors, mainly the stamping die of the stamping machine, or the problem of pneumatic clamps. At present, the market competition in every industry is constantly developing fiercely. The same is true for the CNC stamping industry. Therefore, the quality of products is one of the main reasons affecting corporate competition.In the process of CNC stamping, what are the reasons for the failure of the workpiece? It may be that the difference between the mold and the feeding table is too large. The looseness of the CNC stamping fixture clamp will affect the offset of the feeder plate. Or it is a local failure of CNC stamping, mostly caused by loose screws. CNC stamping driver. Driver alarm, if the CNC stamping machine fails, it will cause the driver alarm. Reduce the occurrence of CNC stamping failures. Ensure the quality of stamping parts, reduce the phenomenon of substandard product quality, and improve corporate productivity.DongGuan Win-Leading Hardware Technology Co., Ltd. has developed over the years and specializes in hardware products such as hardware molds, stamping products, sheet metal bending, laser cutting, CNC processing, etc. with excellent manufacturing level and service attitude. It is known for its influence in the world manufacturing industry and its product supply capacity that is the best in the world. Welcome new and old customers to call for inquiries.