What is the difference between sheet metal processing and hardware processing?

Publish Time: 2024-05-29

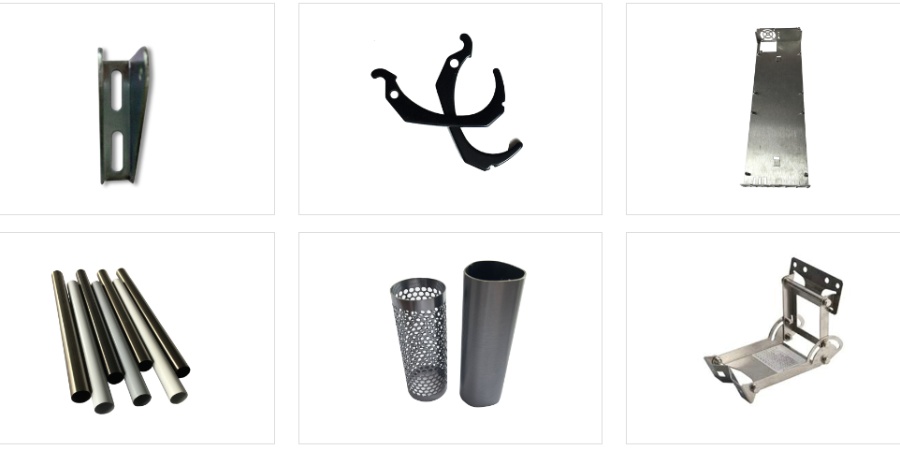

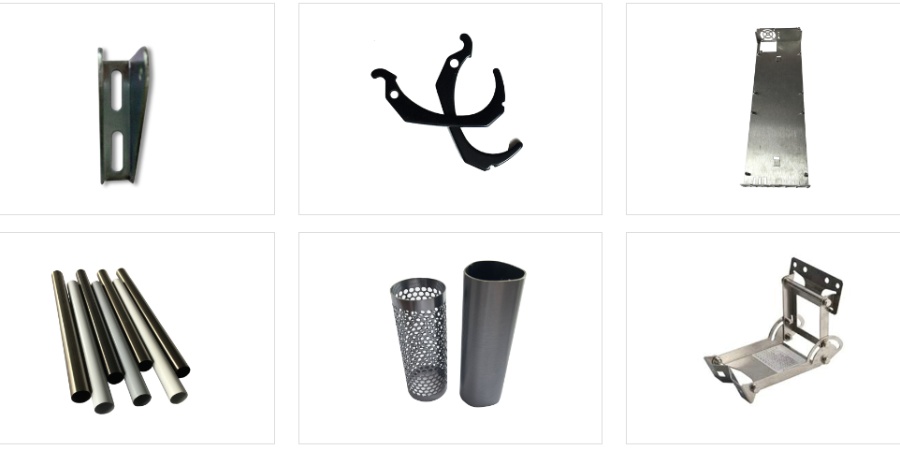

There are significant differences between sheet metal processing and hardware processing in many aspects. The following is a detailed analysis of the differences between the two:Processing objects:Sheet metal processing: mainly using metal sheets for processing, and processing metal sheets into workpieces of the required shape through shearing, stamping, bending, welding and other methods.Hardware processing: processing for metal parts, including casting, forging, stamping, riveting, welding and other methods to manufacture and process metal parts.Application areas:Sheet metal processing: commonly used in the production of various metal products, such as electrical housings, mechanical parts, automotive parts, etc. Sheet metal parts are usually thin metal parts that can be processed by a high degree of stamping, bending, stretching and other processing.Hardware processing: mainly used to produce various hardware products, such as door and window hardware, furniture hardware, building hardware, etc. There are many types of hardware accessories, which need to be customized according to different needs.Processing process:Sheet metal processing: involves shearing, punching, cutting, folding, welding, surface treatment and other steps. This is a process method that uses general mechanical equipment such as metal presses, shears and punches for cold deformation.Hardware processing: The process involved is more complicated, including cutting, stamping, welding, polishing, electroplating, etc. The hardware accessories processing industry has mature technology and has accumulated rich experience to ensure product quality and production efficiency.Customized service:Hardware processing: Due to the wide variety of hardware accessories, the needs of different customers are also different. Therefore, hardware accessories processing companies usually provide customized services and carry out personalized production according to customer needs and requirements.Sheet metal processing: Although it also provides certain customized services, hardware processing is more prominent and common in this regard.Quality assurance:Hardware processing: attaches great importance to quality management, adopts advanced production equipment and technology, and establishes a strict quality management system to ensure that every process from raw materials to finished products meets quality standards.Sheet metal processing: also attaches importance to quality assurance, but it is more prominent in hardware processing.Innovation and development:Both are constantly innovating and improving to meet the needs of the market and customers. However, the hardware accessories processing industry may be more active in continuous innovation, keeping up with market demand and technological development trends, and developing new products and new technologies.In summary, sheet metal processing and hardware processing have obvious differences in processing objects, application fields, processing processes, customized services, quality assurance and innovative development. These two processing methods have their own characteristics and are both important components of the metal processing field. Dongguan sheet metal processing and hardware processing are both common ways of manufacturing metal parts. With the increasing demand for the use of hardware and metal parts in recent years. There are also more requirements in the manufacturing process. What is hardware processing? Hardware refers to five metals: gold, silver, copper, iron, and tin, which are manufactured and formed through various equipment. Used in life or industry, each metal has a special role and use.Dongguan sheet metal processing is a relatively broad definition. The main processing method is stamping. It is directly stamped and formed without changing the original properties of the metal. Most of them are mainly thin plates, which are used for the shells of many equipment or electrical appliances, and there are also some small parts. Generally, Dongguan sheet metal processing is designed according to the customer's use requirements. Various shapes, sizes and other parameters. A small part of hardware processing includes a part of Dongguan sheet metal processing. Although the number of words is different, they are two different processing methods. Dongguan sheet metal processing is a relatively light, fast and reliable processing method for many industry products.DongGuan Win-Leading Hardware Technology Co., Ltd. has developed over the years and specializes in hardware products such as hardware molds, stamping products, sheet metal bending, laser cutting, CNC processing, etc. with excellent manufacturing level and service attitude. It is known for its influence in the world manufacturing industry and its world-class product supply capabilities. New and old customers are welcome to call us for inquiries.

Dongguan sheet metal processing and hardware processing are both common ways of manufacturing metal parts. With the increasing demand for the use of hardware and metal parts in recent years. There are also more requirements in the manufacturing process. What is hardware processing? Hardware refers to five metals: gold, silver, copper, iron, and tin, which are manufactured and formed through various equipment. Used in life or industry, each metal has a special role and use.Dongguan sheet metal processing is a relatively broad definition. The main processing method is stamping. It is directly stamped and formed without changing the original properties of the metal. Most of them are mainly thin plates, which are used for the shells of many equipment or electrical appliances, and there are also some small parts. Generally, Dongguan sheet metal processing is designed according to the customer's use requirements. Various shapes, sizes and other parameters. A small part of hardware processing includes a part of Dongguan sheet metal processing. Although the number of words is different, they are two different processing methods. Dongguan sheet metal processing is a relatively light, fast and reliable processing method for many industry products.DongGuan Win-Leading Hardware Technology Co., Ltd. has developed over the years and specializes in hardware products such as hardware molds, stamping products, sheet metal bending, laser cutting, CNC processing, etc. with excellent manufacturing level and service attitude. It is known for its influence in the world manufacturing industry and its world-class product supply capabilities. New and old customers are welcome to call us for inquiries.