The role of spray painting on the surface of sheet metal processing and the painting steps are summarized as follows:

The role of spray painting on the surface of sheet metal processing

Improve surface quality: spray painting can eliminate dents, defects, etc. on the surface of sheet metal parts, and increase the smoothness and aesthetics of the surface.

Increase wear resistance and corrosion resistance: Through spray painting, the wear resistance and corrosion resistance of sheet metal parts are enhanced, thereby extending their service life.

Increase aesthetics: Spray painting can be applied with different colors and patterns to make the appearance of sheet metal products more beautiful and generous, and increase the added value of products.

Painting steps

Preparation:

Cleaning: Use detergent or solvent to remove dirt and grease on the surface of sheet metal to ensure that the surface is clean.

Repair: Repair the surface, repair any dents, depressions or scratches, and make the surface smooth.

Grinding:

Use a grinding tool to grind the surface of the sheet metal to remove any rough or uneven surfaces.

Pay attention to the strength and angle to avoid further damage to the sheet metal.

Putty repair:

Apply an appropriate amount of putty on the concave or uneven surface and smooth it with a scraper.

After waiting for the putty to cure, use sandpaper to sand the repaired part to make it flush with the surrounding surface.

Primer coating:

Primer provides a uniform color base, increases the adhesion of the paint film, and has a decorative and protective effect.

Dilute the primer to an appropriate viscosity, and then use a spraying device to spray it evenly on the surface.

Grinding:

After the primer dries, use sandpaper or a grinder to grind the primer surface with fine sand to smooth it.

Make sure there are no obvious depressions or protrusions on the surface.

Topcoat coating:

Topcoat gives sheet metal parts rich color and gloss.

After diluting the topcoat to an appropriate viscosity, use a spraying device to evenly apply it on the surface.

Drying and polishing:

Put the sheet metal in the drying equipment to quickly dry the paint film.

Use a polishing machine to polish the sprayed surface to increase gloss and delicate feeling.

Inspection and quality control:

Inspect the painted surface to ensure that there are no obvious flaws or scratches.

Keep the surface smooth and uniform, and perform other processes as needed, such as identification, protective treatment, etc.

The above is a clear overview of the effects and steps of painting on the surface of sheet metal processing. Each step is very important and needs to be carefully operated to ensure the effect and quality of painting.

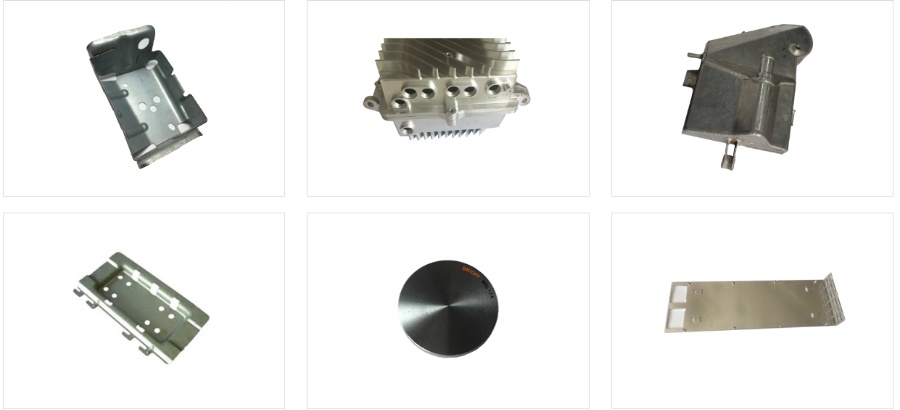

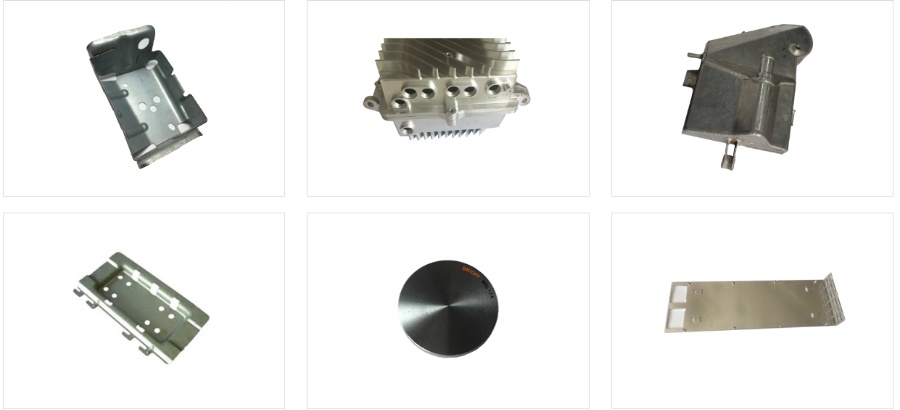

Dongguan sheet metal processing is a process with complex procedures. With the rapid development of the manufacturing industry, the research and technology investment in Dongguan sheet metal processing has been deepened. Make Dongguan sheet metal processing technology more in line with the processing requirements of many manufacturers. Dongguan sheet metal processing has a wide range of applications, including electronics, hardware, mechanical equipment and other industries. In technical processing, Dongguan sheet metal processing is definitely an indispensable processing technology.

Dongguan sheet metal processing has many procedures, and surface treatment is an important procedure. Many sheet metal parts require a strong surface, and the main function of surface processing is to strengthen its essence. Dongguan sheet metal processing surface painting is another process for sheet metal surface processing. The main purpose is to make sheet metal parts have a protective effect, not easily oxidized and rusted, and damage the surface layer. How many steps are there in the surface painting of sheet metal processing in Dongguan? Generally, there are four processes: base treatment, primer, intermediate paint, and finally surface treatment. Each layer is sprayed with different processes and paints.

DongGuan Win-Leading Hardware Technology Co., Ltd. has developed over the years and specializes in hardware products such as hardware molds, stamping products, sheet metal bending, laser cutting, CNC processing, etc. with its excellent manufacturing level and service attitude. It is named for its influence in the world manufacturing industry and its ability to supply products all over the world. New and old customers are welcome to call for inquiries.