Solutions to the deformation of CNC punching holes and thinning of pressed materials caused by precision sheet metal bending processing

Publish Time: 2024-10-14

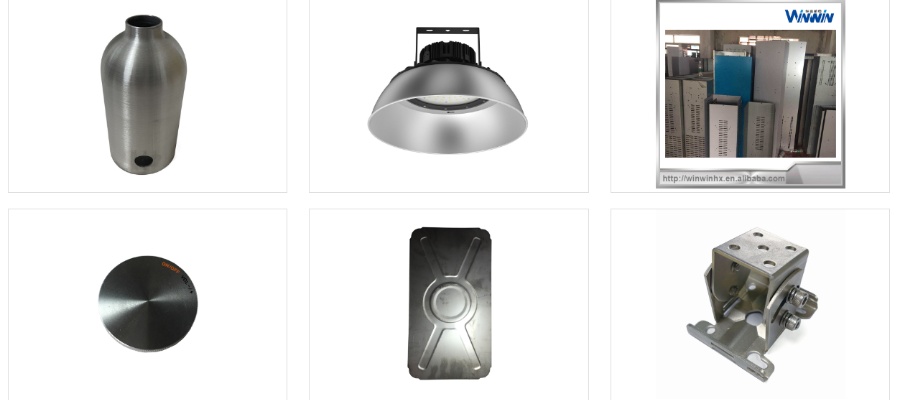

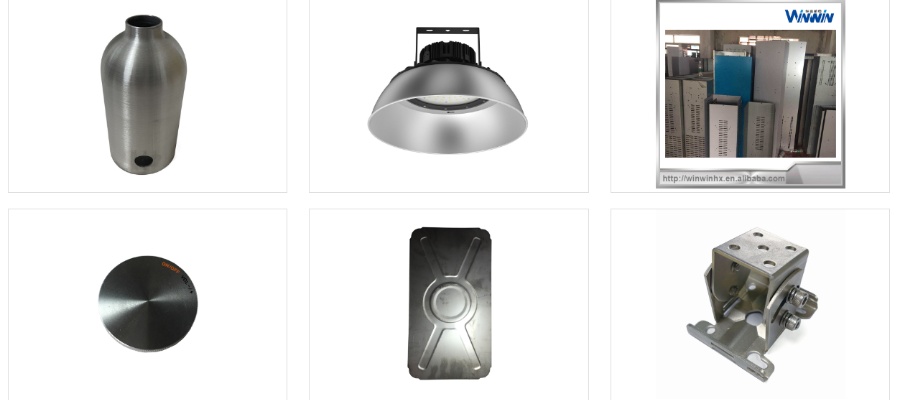

What is precision sheet metal processing? That is, sheet metal parts have higher and more precise processing requirements than other ordinary sheet metal parts. With the rapid advancement of science and technology, many mechanical equipment belong to precision processing equipment. There must be higher requirements for each part of the equipment. In precision sheet metal processing, bending processing is one of the steps that some products must go through. In addition to the perfect dimensional accuracy bending, the bending requirements must also ensure quality changes. In the process of precision sheet metal processing, we found that many sheet metals will have cracks and spots on the back and thinner material thickness when they go through the bending step. Why is this? Precision sheet metal bending processing causes extrusion material deformation. It is very likely that the existence of two problems, such as the radius of the die of the bending machine and the small gap between the convex and concave dies, uses adjustment to increase the radius of the die corner or reduce the gap between the convex and concave dies. In some precision sheet metal parts with CNC punching, the hole deformation will be caused by bending. The pressure of the top plate can be changed, or the friction can be increased to prevent the workpiece from slipping when bending.DongGuan Win-Leading Hardware Technology Co., Ltd. has developed over the years and specializes in hardware products such as hardware molds, stamping products, sheet metal bending, laser cutting, CNC processing, etc. with excellent manufacturing level and service attitude. It is famous for its influence in the world manufacturing industry and its product supply capacity that is the best in the world. Welcome new and old customers to call for inquiries.

In the process of precision sheet metal processing, we found that many sheet metals will have cracks and spots on the back and thinner material thickness when they go through the bending step. Why is this? Precision sheet metal bending processing causes extrusion material deformation. It is very likely that the existence of two problems, such as the radius of the die of the bending machine and the small gap between the convex and concave dies, uses adjustment to increase the radius of the die corner or reduce the gap between the convex and concave dies. In some precision sheet metal parts with CNC punching, the hole deformation will be caused by bending. The pressure of the top plate can be changed, or the friction can be increased to prevent the workpiece from slipping when bending.DongGuan Win-Leading Hardware Technology Co., Ltd. has developed over the years and specializes in hardware products such as hardware molds, stamping products, sheet metal bending, laser cutting, CNC processing, etc. with excellent manufacturing level and service attitude. It is famous for its influence in the world manufacturing industry and its product supply capacity that is the best in the world. Welcome new and old customers to call for inquiries.